Hydraulic Stamping Systems

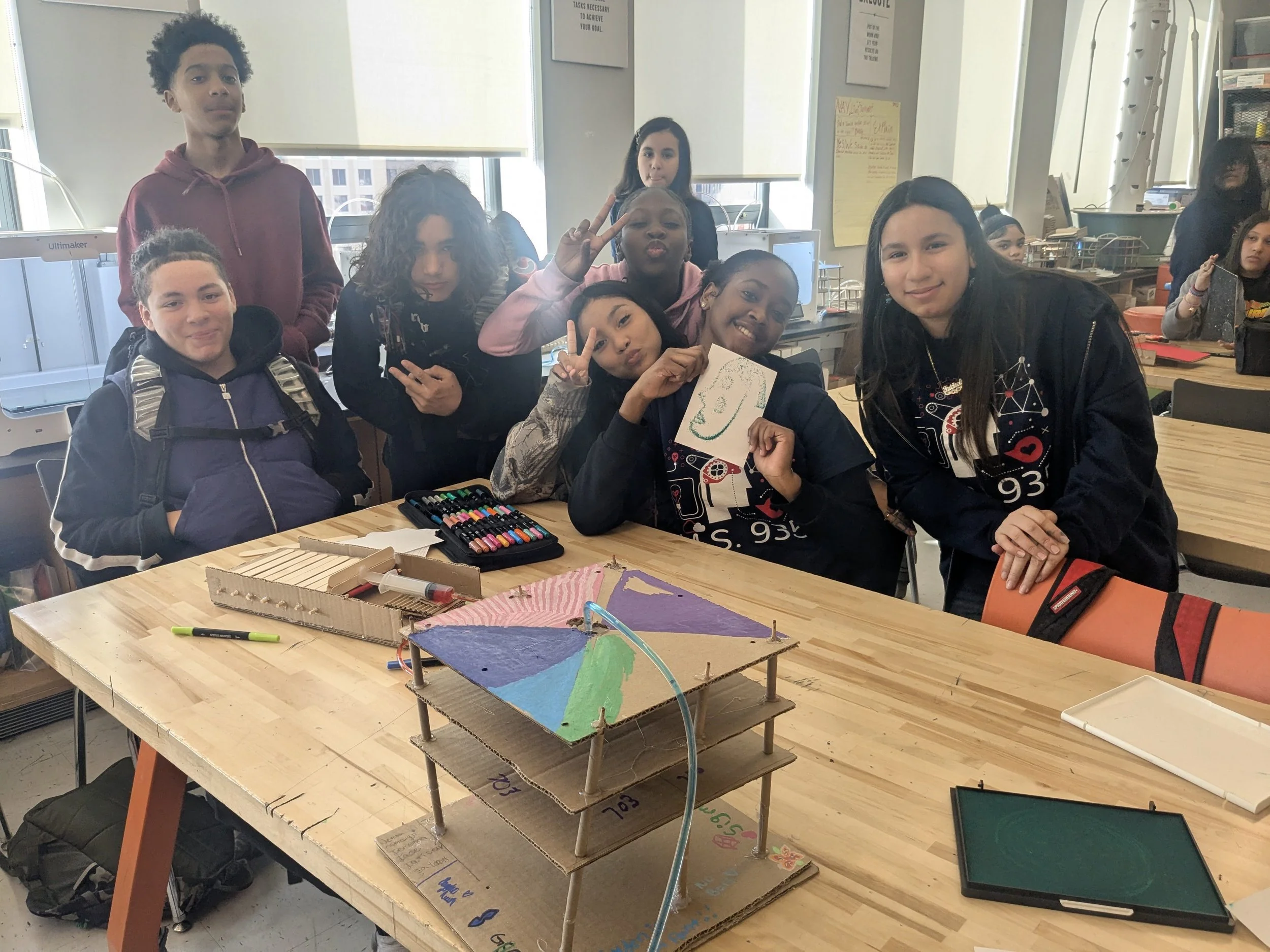

7th Grade Science & Social Studies | MS935, Brooklyn

My Role:

Project Designer - I designed the project from scratch, including prototypes for a hydraulic press and moving bed, lesson plans, and instructional materials.

Project Description:

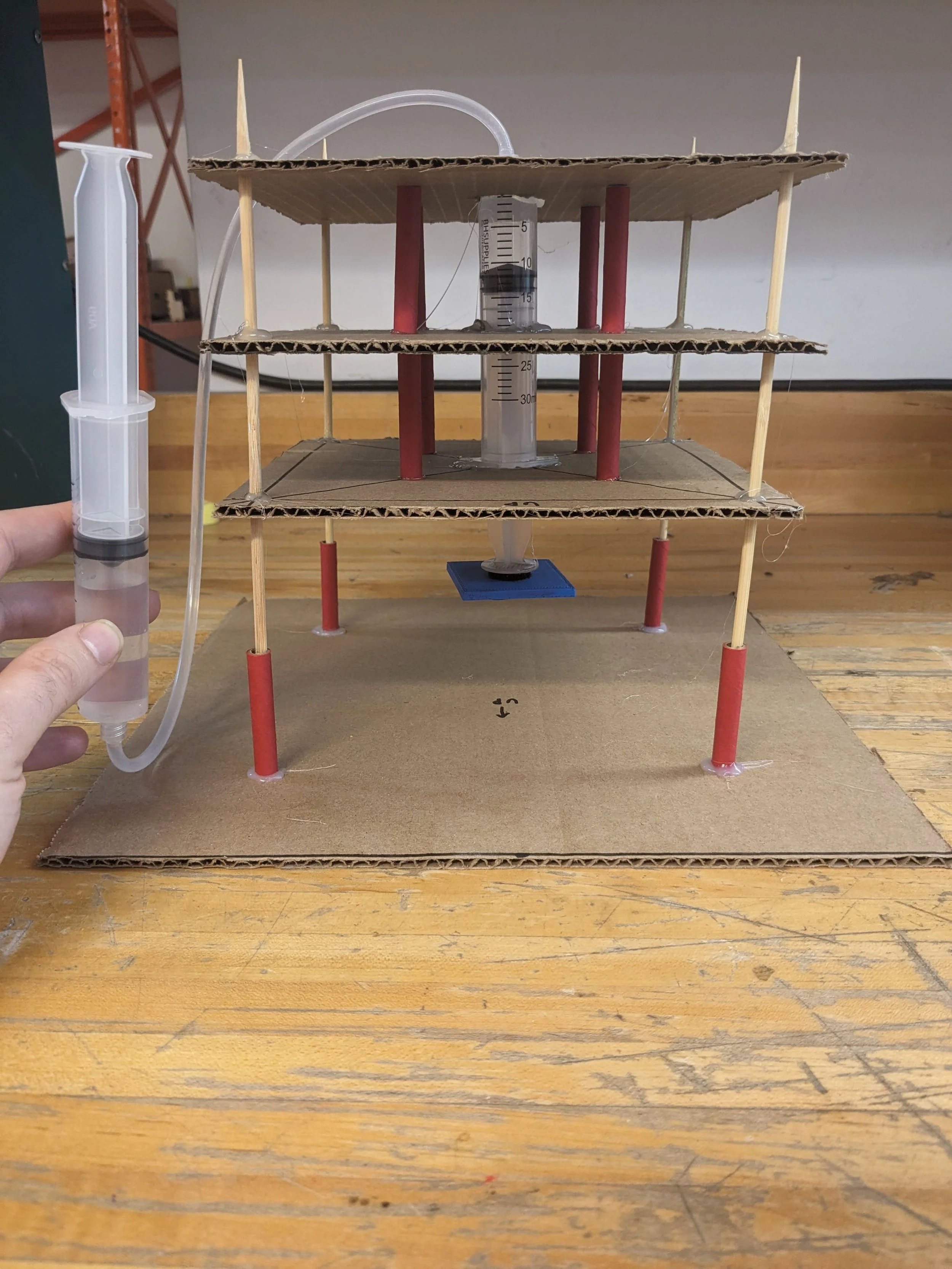

Seventh grade student teams built working hydraulic presses out of cardboard, wooden skewers, and medical syringes connected with tubing and water. They also built accompanying sliding beds that moved ink pads and paper into position using the same principles. Students then designed and 3D printed custom stamps to use with their presses. Tied to a social studies unit on the Industrial Revolution, the project blended analog and digital construction skills, and demonstrated how new technologies enabled consistent and replicable industrial processes.

Design Approach:

I introduced 3D printing both to give students creative investment in the project and to help the school begin integrating its under-used printers into regular classroom instruction. The project deliberately combined analog construction with digital tools, giving students a sense of both tactile making and modern fabrication methods. To emphasize precision and replicability, I opened with a measurement challenge requiring students to cut and align multiple cardboard pieces accurately — a skill critical to the success of their hydraulic builds.

Project Sequence:

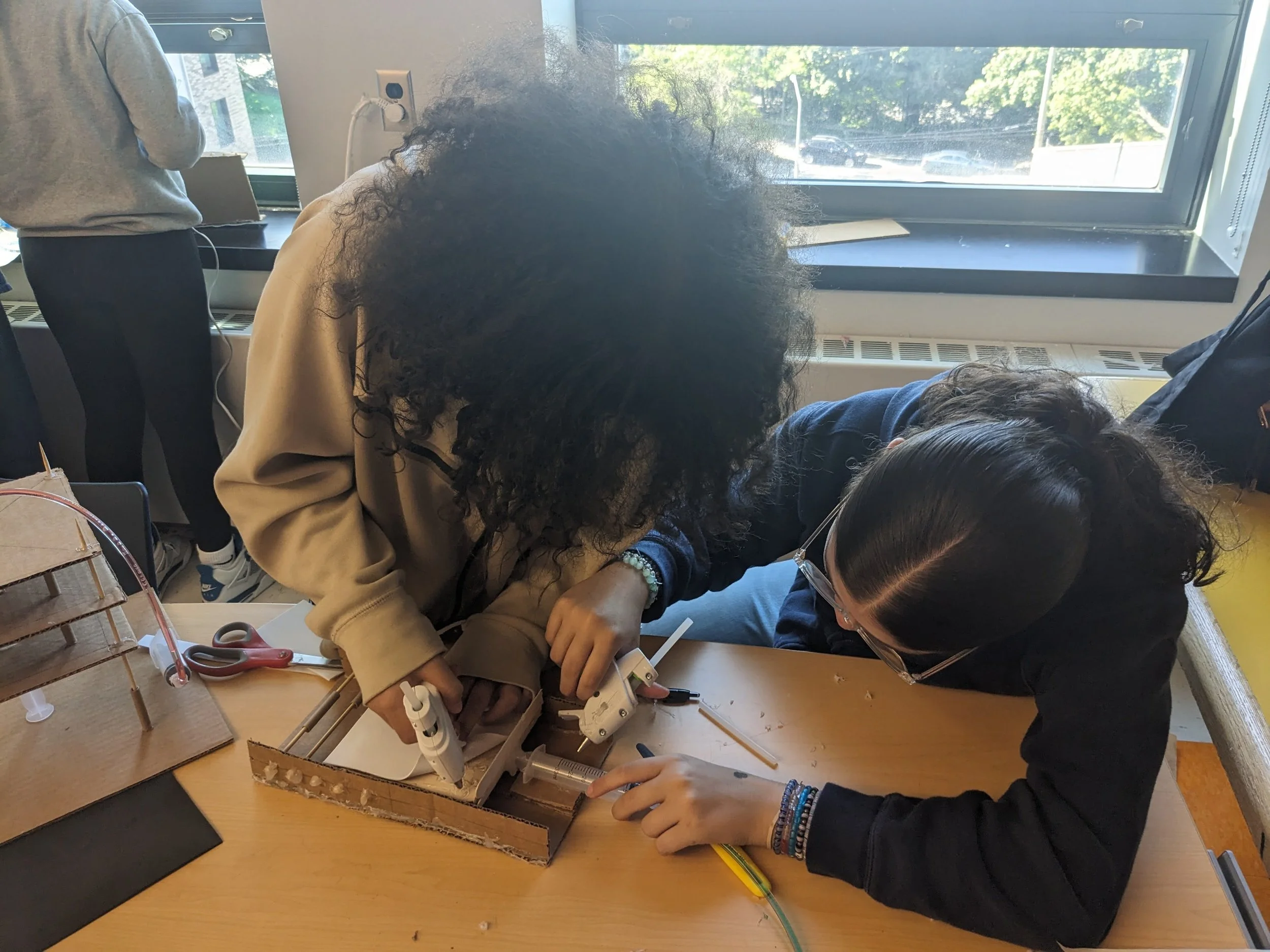

Practiced precision cutting and measuring by creating multiple identical cardboard pieces with aligned holes.

Built cardboard-and-syringe hydraulic presses and sliding beds to move materials into place.

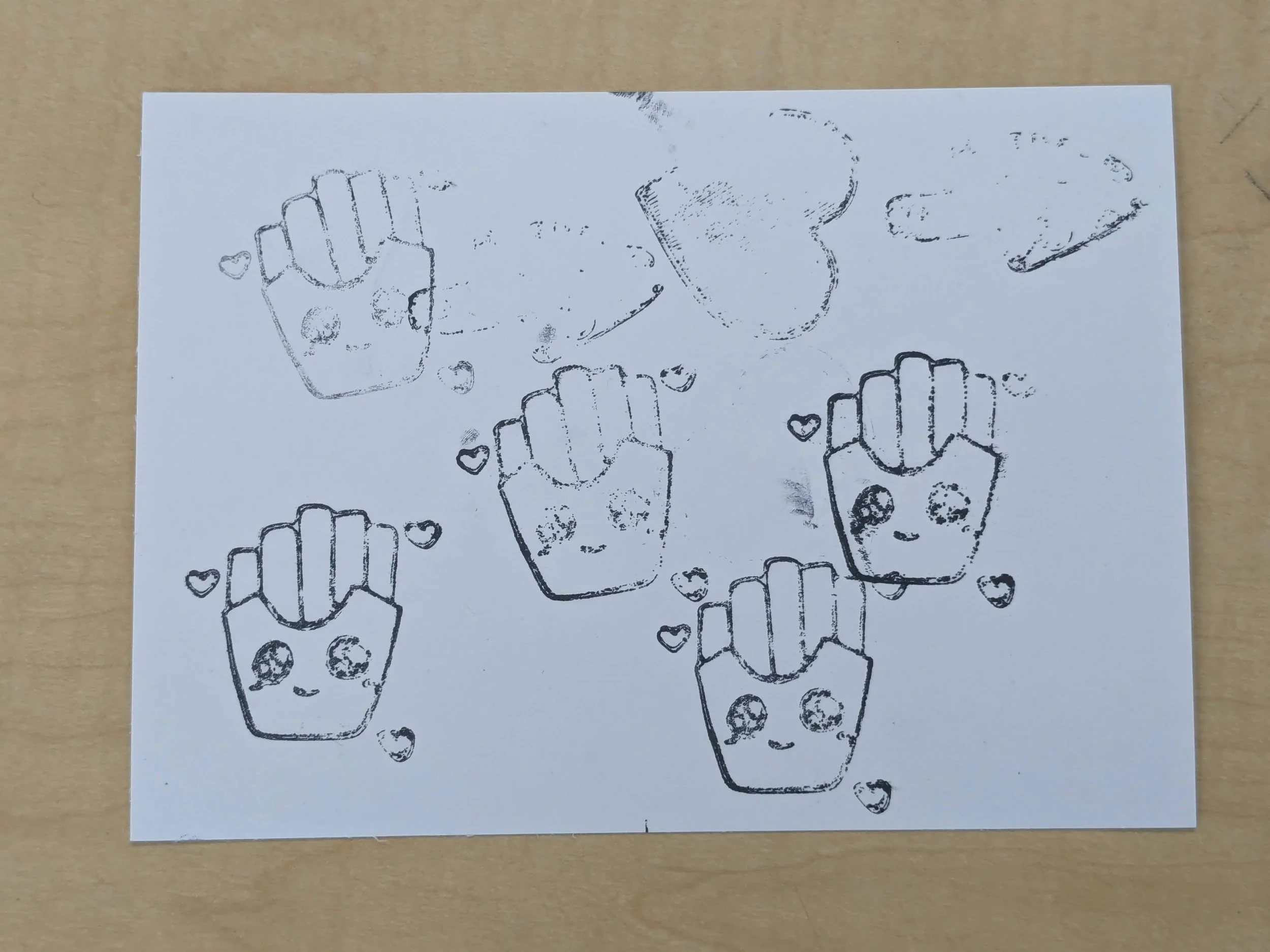

Designed custom stamp patterns in 3D modeling software and printed them using the school’s 3D printers.

Mounted stamps and tested their machines, refining designs and experimenting with placement of hydraulic devices.

Used presses and beds together to produce stamped impressions, simulating early industrial processes.

Student Learning Outcomes:

Practiced precision measurement and understood its role in replicability.

Learned the principles of hydraulics and their applications in machinery.

Gained an introduction to digital fabrication and 3D design.

Developed tool use, construction, and problem-solving skills.

Connected social studies (Industrial Revolution) with science (mechanics, hydraulics, digital fabrication).

Exercised creativity in stamp design and machine customization.